What are hybrid fibres?

All the materials you need, contained in every fibre.

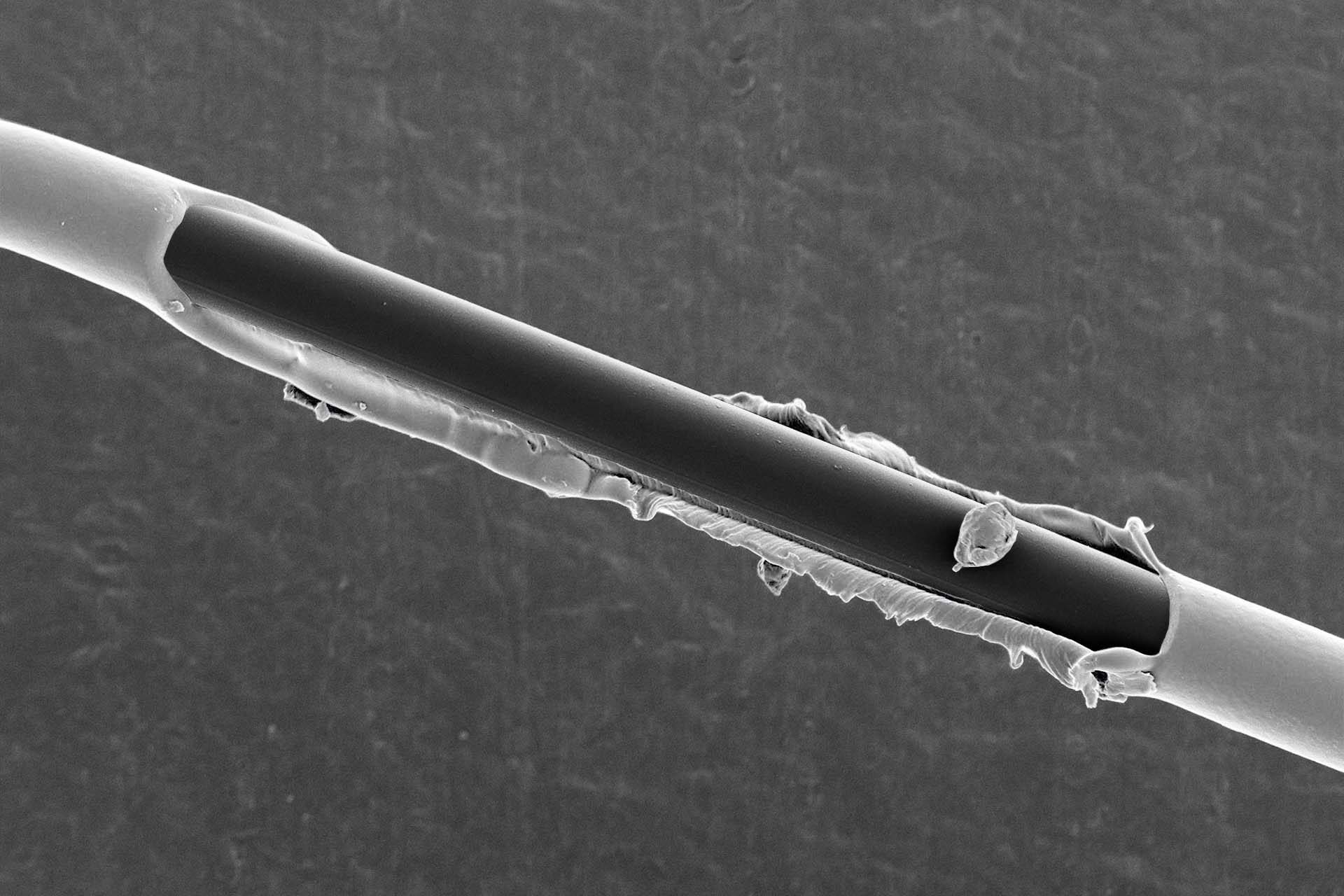

We combine every single reinforcement fiber with the meltable plastic matrix – already on the microscale.

Why hybrid fibres?

Lightweight.

Lightweight and meltable polymer matrix.

Strong.

Strong continuous glass reinforcement fibres.

Saving time.

Shorter cycle times, no curing nor impregnation processes and a lower energy demand.

High quality.

Aerospace grade laminate quality with lowest void content and full fibre wet-out result in high mechanical performance.

Easy switch.

Only minor or no process adaptation needed at all.

Weldable.

No need for adhesives.

Recyclable.

No more landfilling by supporting a circular use of composite materials.

Safe.

No special personal protection needed during processing.

Complex shapes.

Flexible, drapeable textiles enable complex part geometries.

Affordable.

Cost-efficient processing possibilities combined with an affordable feedstock material.

And many more!

With our microengineered hybrid fibres, high quality parts can be manufactured using only heat and a minimum amount of pressure. This makes them interesting for many other applications. Let us know how we can help solve your challenges!